Tel

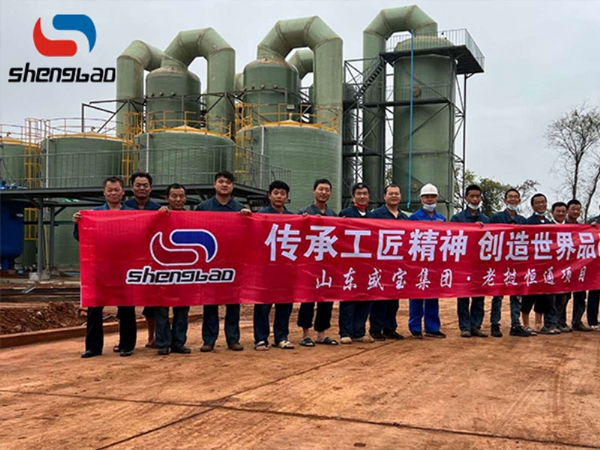

+86 536 4736888Shandong Shengbao Composite material Technology Co., LTD

Consulting equipment: +86-15253666812

After-sales phone: +86-0536-4736888

Email: sbfrp@126.com

Address: West of Jinshan Street, Xinan Street, Anqiu City, Weifang City, Shandong Province

Years of industry experience precipitation, cast mature technology, excellent reputation and reputation.

Fine technology, smooth production and processing configuration, quality over time.

Shuttle to visit the factory

One-to-one after-sales service

Inspect the production site nearby

60 seconds manual response

30 minutes to give a technical reply

24 hours free customization program

The structural design and manufacturing process of the glass steel tower reflects a high degree of technology. Its main structure includes the lining layer, the structure layer and the sealing part.

Lining layer: mainly plays the role of anti-corrosion and anti-seepage, the resin content is high, to ensure the long-term stable operation of the tower.

Structure layer: The spray yarn and glass cloth are alternately laid. Reasonable tension is applied in the laying process of each single layer of glass cloth, and the bubbles are driven out by the combined press roller to ensure that the fiber is completely saturated and the structural strength of the tower is enhanced.

Head: In addition to the lining layer, the head part has a structural layer, which is formed and reinforced by a specific process.

Strong resistance to corrosion and impact

Strong resistance to corrosion and impact Professional installation team quality assurance

Professional installation team quality assurance Stable operation after-sales service

Stable operation after-sales service Strength manufacturers Constantly improve

Strength manufacturers Constantly improve In the bromine industry in the promotion of fiberglass seawater bromine extraction equipment is the first in the country, in 2003, on the basis of the original PVC, cement tower anti-corrosion, and several domestic large bromine production units of technical experts successfully developed a set of fiberglass seawater bromine extraction equipment, and in 2004 in Changyi sea Bromine plant successful operation.

In 2023, it will process and produce 9500 diameter seawater bromine extraction equipment for "Shandong Haihua Group" with a single production capacity of 2000T/ year, which is also the largest diameter seawater bromine extraction equipment in the world up to now.

Successfully produced more than 320 sets of bromine extraction equipment for more than 100 domestic FRP seawater, accounting for more than 95% of the domestic market share.

In 2008, seawater bromine extraction equipment went out of the country to the world, and more than 60 sets of complete equipment have been produced in India, Djibouti, Laos, Russia, Ethiopia and other countries.

Seawater bromine extraction equipment patents 11.

High temperature heat treatment, casting, cooling and other links in the process of steel production.

Mainly used to cool the generator air, water vapor and other media.

Deal with all kinds of harmful gases, such as waste gas treatment, flue gas desulfurization and denitrification.